Green Sand Molding Line

Green Sand Molding Line

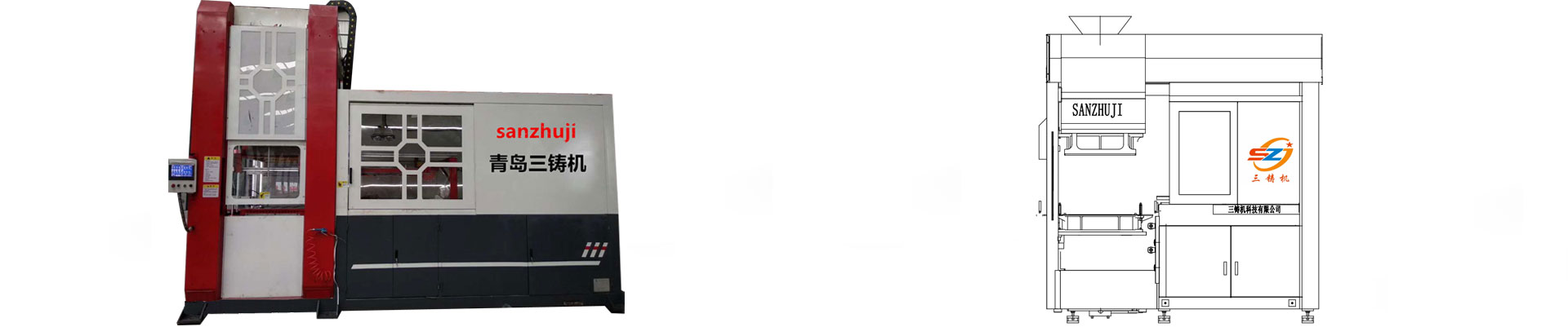

Green Sand Molding Line is mainly composed of Sand molding machine, rotator mixer, sand conveying belt, vibrating shakeout machine, magnetic separator, riddle, boiling cooling equipment, bucket elevator, sand storehouse, quantitative device and screw feeder and other equipment.

Product Introduction

Green Sand Molding Line is mainly composed of Sand molding machine, rotator mixer, sand conveying belt, vibrating shakeout machine, magnetic separator, riddle, boiling cooling equipment, bucket elevator, sand storehouse, quantitative device and screw feeder and other equipment. Sanzhuji can according to casting Workshop size custom design scheme.

Green sand production line process: Clay sand is a modeling (core) sand with clay as a binder. Mechanizing the sand recovery process is an important part of foundry production. The quality of the casting sand recovered after pouring directly affects the production quality and output of castings, and reduces costs. Due to the complex recycling and treatment process of used sand, the processing and transportation of green sand is very heavy, and the environment is very harsh, so the mechanization of sand recycling and treatment process is an important part of foundry production. After pouring and cooling, the sand mold is separated by a vibrating shakeout machine (drum shakeout machine) to complete the separation of the casting sand. The hot castings are transported to the shot blasting area by a scale conveyor. The sand outlet of the shakeout machine is equipped with a belt conveyor to transport the old sand in the regeneration area, the suspended magnetic separator and the belt conveyor r are placed crosswise to remove the iron beans in the old sand. The dust in the old sand is removed through the dust removal port, and the screened old sand enters the small sand silo, the old sand is cooled by the boiling cooling bed, and the 2# bucket elevator vertically lifts the old sand to the sand silo for storage. The unloader distributes the old sand to the 2# sand bin, the 3# sand bin, and the bottom of the sand bin will be equipped with a vibrating disc feeder. The old sand falls into the belt conveyor and is transported to the storage hopper of the rotor sand mixer, coal powder, The bentonite is added to the auxiliary electronic scale through the screw feeder, and then enters the rotor sand mixer for mixing after uniform proportioning. After the sand loosening machine is processed, it is transported to the molding machine for a new round of molding use.

Green sand production line process: Clay sand is a modeling (core) sand with clay as a binder. Mechanizing the sand recovery process is an important part of foundry production. The quality of the casting sand recovered after pouring directly affects the production quality and output of castings, and reduces costs. Due to the complex recycling and treatment process of used sand, the processing and transportation of green sand is very heavy, and the environment is very harsh, so the mechanization of sand recycling and treatment process is an important part of foundry production. After pouring and cooling, the sand mold is separated by a vibrating shakeout machine (drum shakeout machine) to complete the separation of the casting sand. The hot castings are transported to the shot blasting area by a scale conveyor. The sand outlet of the shakeout machine is equipped with a belt conveyor to transport the old sand in the regeneration area, the suspended magnetic separator and the belt conveyor r are placed crosswise to remove the iron beans in the old sand. The dust in the old sand is removed through the dust removal port, and the screened old sand enters the small sand silo, the old sand is cooled by the boiling cooling bed, and the 2# bucket elevator vertically lifts the old sand to the sand silo for storage. The unloader distributes the old sand to the 2# sand bin, the 3# sand bin, and the bottom of the sand bin will be equipped with a vibrating disc feeder. The old sand falls into the belt conveyor and is transported to the storage hopper of the rotor sand mixer, coal powder, The bentonite is added to the auxiliary electronic scale through the screw feeder, and then enters the rotor sand mixer for mixing after uniform proportioning. After the sand loosening machine is processed, it is transported to the molding machine for a new round of molding use.

L25 Series conveyer shakeout:Separation of green sand and castings by vibration, high temperature resistance efficiency and low energy consumption

The role of this shakeout machine is to separate molding sand castings by vibration, which is the first link of the old sand treatment system and the boundary between the molding department and the sand treatment department. This series shakeout machine is suitable for shakeout and casting transportation of molding line, high temperature sand mold, with high production efficiency and low cost. Low energy consumption, good environmental protection and other characteristics.

The role of this shakeout machine is to separate molding sand castings by vibration, which is the first link of the old sand treatment system and the boundary between the molding department and the sand treatment department. This series shakeout machine is suitable for shakeout and casting transportation of molding line, high temperature sand mold, with high production efficiency and low cost. Low energy consumption, good environmental protection and other characteristics.

L series falling sand cooling roller:The collision and friction of the castings are used to separate the castings and the sand mold, and at the same time achieve the function of cooling the sand temperature.

When the mold of the sand box is rotated to a certain height, it falls to the bottom of the simplified box by its own weight. Under the mutual impact and friction, the sand mold and the casting separation well reach the simplified box grid along the direction of the spiral plates. The sand enters the old sand system and the casting is discharged through the discharge port.

When the mold of the sand box is rotated to a certain height, it falls to the bottom of the simplified box by its own weight. Under the mutual impact and friction, the sand mold and the casting separation well reach the simplified box grid along the direction of the spiral plates. The sand enters the old sand system and the casting is discharged through the discharge port.

S99 series hanging permanent magnet separator:Magnetic separation equipment, remove the inclusions in the old sand, according to the conveyor belt width matching design

S99 series permanent magnet separation equipment, using high magnetic material, has strong magnetic strength. It is widely used in metallurgy, mining, power generation, building materials, casting and other industries. The magnetic system is slow in aging and long in life, with a decrease of only 18% in 5-7 years. It is still close to the electromagnetic separation equipment.

S99 series permanent magnet separation equipment, using high magnetic material, has strong magnetic strength. It is widely used in metallurgy, mining, power generation, building materials, casting and other industries. The magnetic system is slow in aging and long in life, with a decrease of only 18% in 5-7 years. It is still close to the electromagnetic separation equipment.

Bucket elevator:It is an upgraded product of D-type bucket elevator, used for vertical conveying of old sand

Bucket elevator is a national standard product. It is a modified product of d-type bucket elevator. It is suitable for vertical upward transportation of old sand, waste sand, new sand, cleaning iron shot and other granular, small block without grinding or semi-grinding powder materials. Its structure characteristic: the appearance size is small, the occupation area is little, the promotion height is big, the installation maintenance is convenient. There are two kinds of feeding methods: the receiving type and the taking type at the bottom. The material is transported to the top and discharged by centrifugal gravity.

Bucket elevator is a national standard product. It is a modified product of d-type bucket elevator. It is suitable for vertical upward transportation of old sand, waste sand, new sand, cleaning iron shot and other granular, small block without grinding or semi-grinding powder materials. Its structure characteristic: the appearance size is small, the occupation area is little, the promotion height is big, the installation maintenance is convenient. There are two kinds of feeding methods: the receiving type and the taking type at the bottom. The material is transported to the top and discharged by centrifugal gravity.

S43 series riddle:Special screening equipment for green sand, which can control the silt content of old sand and cool the sand temperature

Large end feeding and small end discharging (spindle tilting installation) are adopted to improve the screening ability. Due to the high speed, the material falls from the near high point to achieve crushing and screening.

The long hole net adopts cold-drawn stainless steel braided net, with long service life, especially suitable for hot and humid materials. The hexagon outside the screen is tensioned or fixed with each other, the surface of the screen is not easy to break, good rebound effect, and easy to replace.

Strong ventilation is used in the air inlet to cool the sand and control the mud content of the old sand.

Large end feeding and small end discharging (spindle tilting installation) are adopted to improve the screening ability. Due to the high speed, the material falls from the near high point to achieve crushing and screening.

The long hole net adopts cold-drawn stainless steel braided net, with long service life, especially suitable for hot and humid materials. The hexagon outside the screen is tensioned or fixed with each other, the surface of the screen is not easy to break, good rebound effect, and easy to replace.

Strong ventilation is used in the air inlet to cool the sand and control the mud content of the old sand.

S86 series boiling cooling bed:Continuous cooler, under the action of strong wind and cooling water, the old sand is quickly cooled and demoulded

This series of equipment is a continuous cooler, loose old sand into the cooling bed, in the case of high pressure fan strong blast, boiling state, and from the inlet began to wind around the coil cooling pipe meandering forward, in the strong suction and cooling water, the old sand can be fully cooled film removal.

This series of equipment is a continuous cooler, loose old sand into the cooling bed, in the case of high pressure fan strong blast, boiling state, and from the inlet began to wind around the coil cooling pipe meandering forward, in the strong suction and cooling water, the old sand can be fully cooled film removal.

S83 series double disc stirring cooler:Special cooling equipment for green sand can achieve the function of pre-mixed sand. According to different installation positions, two unloading methods can be used, left and right.

This machine is mainly used for the cooling of old clay sand. The sufficient movement makes the temperature, humidity and composition of the old sand uniform. The machine has compact structure, stable movement, low energy consumption and good cooling effect. The high pressure fan makes the old sand in the boiling state to achieve the best cooling effect. The opening of unloading door can be adjusted to control the amount of material in salt. The machine and the old sand automatic temperature and humidification system and blower, induced fan, water system can constitute a complete and ideal old sand cooling unit.

This machine is mainly used for the cooling of old clay sand. The sufficient movement makes the temperature, humidity and composition of the old sand uniform. The machine has compact structure, stable movement, low energy consumption and good cooling effect. The high pressure fan makes the old sand in the boiling state to achieve the best cooling effect. The opening of unloading door can be adjusted to control the amount of material in salt. The machine and the old sand automatic temperature and humidification system and blower, induced fan, water system can constitute a complete and ideal old sand cooling unit.

BLT series scale conveyor:For the transportation of hot castings

Scale board conveyer is a kind of general fixed mechanical conveying equipment, using the steel plate to do the carrying tank, which can be used for a large number of bulk material and a single weight transport. It is especially suitable for large, heavy, hot and corrosive materials, and can be used to clean the pouring riser, cooling, drying, heating, cleaning and sorting in the process of conveying. Widely used in machinery, casting, metallurgy, chemical industry, building materials, power, mining and other industrial sectors.

Compared with BLT scale plate conveyor, JYB scale plate conveyor has high traction, good groove plate rigidity and impact resistance, so it is more suitable for conveying hot heavy castings and forgings.

Scale board conveyer is a kind of general fixed mechanical conveying equipment, using the steel plate to do the carrying tank, which can be used for a large number of bulk material and a single weight transport. It is especially suitable for large, heavy, hot and corrosive materials, and can be used to clean the pouring riser, cooling, drying, heating, cleaning and sorting in the process of conveying. Widely used in machinery, casting, metallurgy, chemical industry, building materials, power, mining and other industrial sectors.

Compared with BLT scale plate conveyor, JYB scale plate conveyor has high traction, good groove plate rigidity and impact resistance, so it is more suitable for conveying hot heavy castings and forgings.

S35 series sand cutter:The special crusher for green sand (wet sand) in the old sand recovery system is equipped with dust collector

The machine is used to loosen the molding sand or break the old sand after flling on the assembly line of mechanized sand

treatment of wet molding. When used for crushing old sand, the dust collector shall be connected to the dust collector.

The machine is used to loosen the molding sand or break the old sand after flling on the assembly line of mechanized sand

treatment of wet molding. When used for crushing old sand, the dust collector shall be connected to the dust collector.